We Powered

We are Powered with QAS

Continuously monitor the quality levels and initiate action to maintain the highest levels of customer satisfaction. Update our technology & skill-sets in order to provide effective and defect free print solutions. Communicate with customers to fully understand their exact requirements and Job specifications to meet their requirements. We deliver on time and constantly interact with the production team to prioritize to meet the promised delivery time.

We are powered with JPMS

Our Job Profile Management System (JPMS) built to help you efficiently manage the complete identification of your Job records. Electronic work instructions (job card) are used for production purposes and to show the status of the Job across the organisation. Tracking of all jobs for re-printing without involving any communication errors. Moreover, this step of ours has earned us lots of appreciation and we look forward to keep up the respect that has been granted to us.

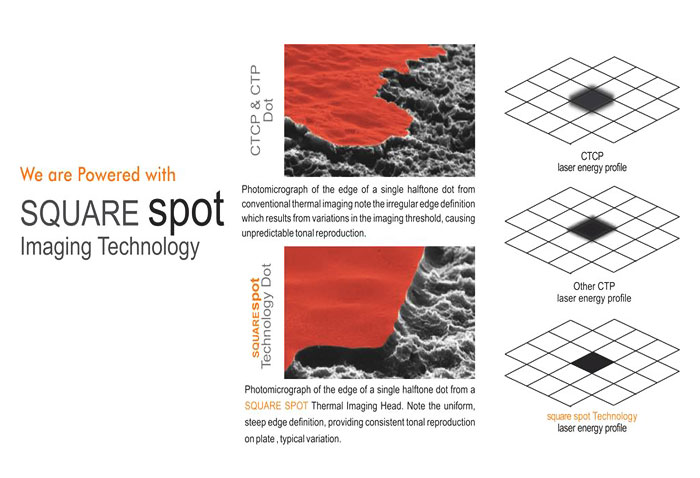

WE ARE POWERED WITH SQUARE SPOT TECHNOLOGY

Even after processing, the edges of dots can be weaker than the center, resulting in quicker dot wear on press, longer make readies, differences between plate readings and press results, and more color variation through the print run. Dots created with SQUARE spot Technology have harder edges, making them more resistant to wear on press than CTCP or Violet dots. Stable, durable dots improve color consistency on press, reduce make ready time, and increase the useful run length of plates on press.